Views: 0 Author: Site Editor Publish Time: 2022-11-02 Origin: Site

Introduction

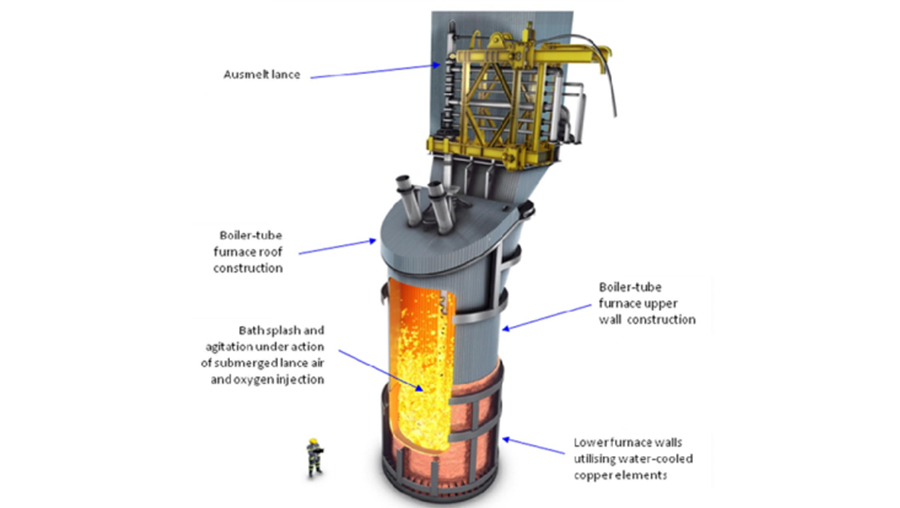

| Ausmelt/Isasmelt copper smelting entails dropping moist solid feed into a tall cylindrical furnace while blowing oxygen-enriched air through a vertical lance into the furnace's matte/slag bath. The products of the process are a matte/slag mixture and a strong SO2 offgas. The matte/slag mixture is tapped periodically into a fuel-fired or electric setting furnace for separation. The settled matte (~60% Cu) is sent to conventional converting. The slag (0.70% Cu) is discarded. The offgas (25% SO2) is drawn from the top of the smelting furnace through a vertical flue. It is passed through a waste heat boiler, gas cleaning and on to a sulfuric acid plant. A small amount of oxygen is blown through the side of the smelting furnace or lance (about halfway up) to ensure that sulfur leaves the furnace as SO2 rather than S2. This prevents sulfur condensation in the gas cleaning system. Most of the energy for smelting comes from oxidizing the concentrate charge. Additional energy is provided by combusting (i) oil, gas, or coal fines blown through the vertical lance and (ii) coal fines in the solid charge |

| Gas Phase Region The refractories needs to withstand the chemical carrion and physical abrasion by the gas stream, impact of thermal shock as well as mechanical damage by falling slags. Combinations of GW-BL and GW-CL are suitable for use in this region |  | |

| Molten Pool Region Need to withstand violent abrasion by the melts and chemical corrosion by the slags. May choose suitable GW-AL series materials according to the type of slags and working temperature range. | |

Weir Mouth This is the region with the worst work conditions when the matte or slags are drained to the chute. The refractories need to withstand the mechanical abrasion of the melts,chemical attach from the slags and damages from thermal shocks.GW-AL-AJ series materials are suitable. |  |